Shandong Lehman Construction Machinery Co., LTD.

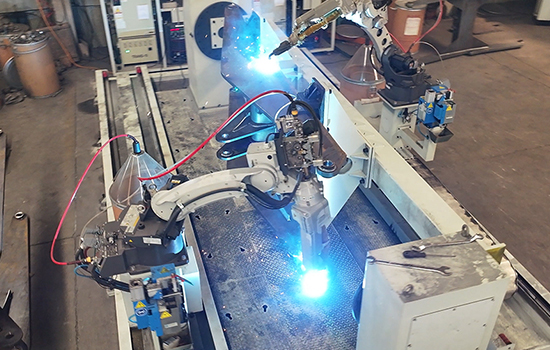

Shanyi Lehman hydraulic oil hose adopts three-layer steel wire design, high pressure resistance, high temperature resistance, corrosion prevention, specially customized American a standard h-type double sealing joints, to put an end to the oil leakage phenomenon of the oil hose. And the aperture is larger, faster oil speed, greatly improving the efficiency of the work. Other companies in the same industry it is still using the old bend through the line tubing, can not resist high pressure, high temperature, poor sealing, oil leakage and oil seepage phenomenon is obvious and aperture is small, over the oil speed is slow and low efficiency, the mountain a Lehman full range of models speed limiters, the use of flame-retardant, kits, to put an end to the line short-circuiting caused by the vehicle on fire situation. Other companies in the same industry use Vantone speed limit, once the speed limit into the water, short-circuit caused by fire, burning cars abound! After looking at the front frame and then take a look at the back half of the shovel cab using thickened steel soft package design, open vision, driving comfort, debuggable soft package, cloth seats, large travel sub-speed, operating handle, distributor, easy to feel the operation, the use of noise reduction and shock absorption combination of the pad to minimize the driver’s fatigue, feel the […]

English

English

Russian

Russian

Arabic

Arabic